Materiais de aplicación: Fiber laser cutting equipment is suitable for metal metal cutting such as stainless steel sheet, carbon steel sheet, alloy steel plate, copper steet, gold plate,sliver plate, titanum plate, steel sheet, tubes and pipes etc.

Industrias de aplicacións: Jewelry, kitchen ware, chassis and cabinet, metal pipe, lamp & lanterns, metal ware, hardware, precision machinery, auto parts, elevator, nameplate, advertisement, eyes glasses, electrical appliance, electronics, micro-electronics, toys and other industries.

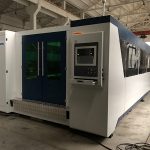

Fiber laser machine 1530 with standard configuration.

#. Heavy duty structure 3500kg

#. Raycus laser generator

#. WSX brand cutting head

#. Cyput controller system with wireless hand-wheel

#. X Y axis JapaneseYaskawa servo motor 850w, Z axis panasonic servo motor 400w

#. Taiwan APEX gear and rack

#. Taiwan Hiwin guide rails 30mm

#. Rack and pinion transmission

#. Japanese SMC Airtac pneumatic element

#. Industrial water chiller

#. French MOTOVARIO reducer

#. French Schneider Electronic Components

#. Including computer

Machine features of fiber laser machine 1530.

(1) High quality laser beam: smaller focal spot, refined cutting kerfs, higher working efficiency, better processing quality.

(2) Rapid cutting speed: the cutting speed is twice as fast as CO2 laser (cutting with equal laser power)

(3) Stable performance: laser device lifetime long;

(4) High photoelectric conversion ratio: its efficiency is 3 times higher than common co2 laser, and it is energy-saving and environmentally friendly;

(5) Low running costs: gross power is just 20-30% of CO2 laser.

(6) Low maintenance costs: no working gas for laser device; optical fiber transmission doesn’t need reflecting mirrors, which save lots of maintenance costs.

(7) Easy operation and maintenance: optical fiber transmission and no need to adjust the optical path;

(8) Flexible optical effects: compact volume and structure, easy to meet the requirement of flexible manufacturing.

Machine parameters of fiber laser machine 1530.

| Área de traballo | 1500 * 3000mm |

| Espesor de corte | 0,2-12 mm |

| Potencia láser | Raycus 500w/750w/1kw//1.5kw/2kw/3kw fiber laser |

| Lonxitude de onda láser | 1080nm |

| Rated power | 10-100% |

| Sistema de control | Cypcut controller system |

| Laser head | WSX brand cutting head |

| Guide rail | Taiwan HIWIN linear guide rails 30mm |

| Transmisión | Taiwan APEX gear and rack transmission |

| Electronic Components | French Schneider |

| X Y axis Motor | X Y axis Japanese Yaskawa servo motor 850w |

| Z axis Motor | Z axis Panasonic 400w servo motor |

| X.Y axis location accuracy | ± 0,01 mm |

| X.Y axis repeat location accuracy | ± 0,01 mm |

| X.Y axis max moving speed | 90m/min |

| Velocidade máxima de corte | 50-60m/min |

| Z axis max speed | 30m / min |

| X axis max acceleration | 1G |

| Y axis max acceleration | 1G |

| Camiño de arrefriamento | Industrial water chiller 6000w |

| Min line width | 0,1 mm |

| Requisitos de enerxía | 380V, 50/60Hz |

| Tempo de traballo continuo | 24 horas |

| Peso | 3600kg |

| Packing size | 480*220*210cm |

sample

1. Applied Industries.

Aplicado en procesamento de chapas, aviación, voo espacial, electrónica, electrodomésticos, pezas de metro, automóbil, maquinaria, compoñentes de precisión, buques, equipamentos metalúrxicos, ascensor, electrodomésticos, agasallos e artesanía, procesamento de ferramentas, adorno, publicidade, procesamento de metais estranxeiros diversos. industrias transformadoras de fabricación.

2. Applied Materials.

Mainly used for cutting carbon steel, stainless steel, aluminum, copper and many kinds of metal materials cutting.

Os nosos Servizos

1.1 year quality guaranty,the machine with main parts(excluding the consumables)shall be changed free of charge if there is any problem during the guaranty period.

2.Mantenemento continuo de balde.

3. Free training course at our plant.

4. We will provide the consumable parts at an agency price when you need replacement.

5. 24 hours on line service each day, free technical support.

6. Machine has been adjusted before delivery.

7. Our staff can be sent to your company to install or adjust if necessary.