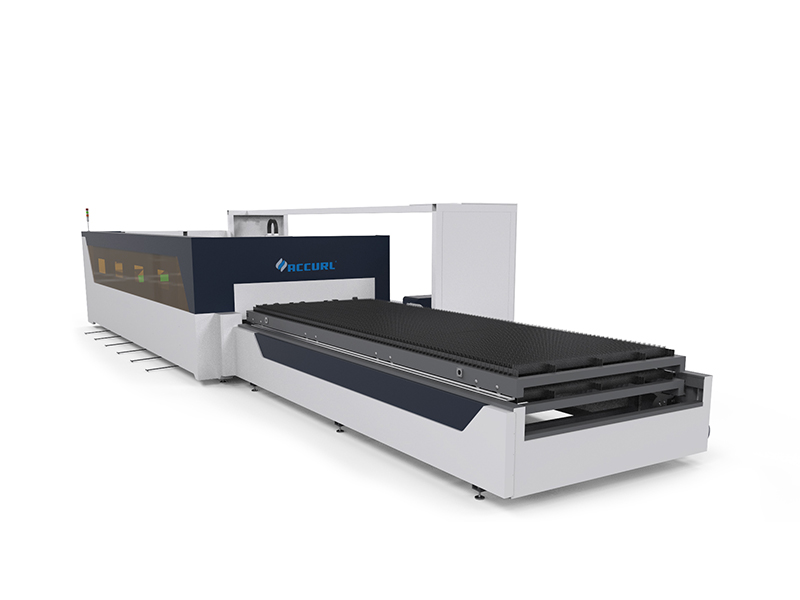

Descrición detallada do produto

| Número de modelo: | KJG-1530DT-1000W ACCURL | Rango de traballo: | 1500x3000mm |

|---|---|---|---|

| Tipo láser: | China Raycus Fiber YLS-1000w | Guía Lineal: | Taiwán HIWIN |

| Chiller: | S&A para fonte de láser e cabeza de corte | Palabras clave: | 1000w Fiber Laser Tube Cutting Machine |

1000w Fiber Laser Tube Cutting Machine for Metal Sheet of Aluminum Alloys 3mm

Accurl's presenta a súa nova xeración en tecnoloxía de procesamento de tubos e perfís: o sistema de corte de tubos con láser de fibra. Con máis de 30 anos de experiencia en deseño e fabricación en tecnoloxía de corte de tubos, Accurl está especializada en solucións para as industrias de tubos e tubos, e a nova liña de corte de tubos con láser é a solución definitiva para unir múltiples procesos de mecanizado nun só sistema para obter a máxima flexibilidade. , automatización e rendemento.

Fiber Laser Tube Cutting Machine características

1. Capacidade ata OD 152 mm

2. Lonxitudes de corte de ata 2000 mm ou 3000 mm (longitudes máis longas a petición)

3. Espesor da parede de 0,6 a 6,0 mm (aceiro suave)

4. Sistema automático de carga de paquetes con aliñación de material

5. Sistema de Descarga Automática con Transportador

6. Equipado con resonador láser de 1,0 kW (estándar) ou 2,0 kW (opcional)

7. Controis CNC multieixes con interface de pantalla táctil

8. Sistema SOCO CAD-CAM para Tubos e Perfís con Nesting incorporado

9. Software de operación 3D SOCO i2 (Interfaz intelixente).

10. Cutting for round, square, rectangle and various profile shapes

11. Enclosed Workstation for maximum safety

EQUIPO ESTÁNDAR

1. Eixe 3 (X, Y, Z)

2. Safety Cabinet

3. Mesa de transporte automático-dual

4. Software CAD/CAM

5. Transportador

6. Lámpada de aviso

7. Conxunto de boquillas

8. Táboa de limpeza de toberas e calibración de altura

EQUIPO OPCIONAL

1. Tecnoloxía do motor lineal

2. Opcións IPG 0,5 kW, 1 kW, 2 kW, 3 kW, 4 kW e 6 kW

3. Unidade de extracción.

4. Barre de protección contra a luz

5. Sistema de soporte de chapas pneumáticos para deslizamiento fácil

6. Aire acondicionado para panel de automatización

7. Software Metalix, Almacam etc. CAD / CAM

8. Cambiador de boquillas

Fiber Laser Tube Cutting Machine Working Processes

1. Automatic Tube Bundle Loading

2. Automatic Material Alignment

3. Automatic Feeding and Rotation

4. Fiber Laser Tube Cutting

5. Unloading

Características do produto

1. Alta potencia de saída, 500-2000 watts é opcional.

2. Pode cortar a superficie de truncamento inclinada no extremo dos tubos.

3. Pode cortar a liña de intersección do tubo de ramal, que se cruza co tubo principal circular.

4. Pode cortar tubos cadrados e facer un corte de xiro de 360 graos.

5. Pode cortar buratos cadrados, buratos tipo cintura nos tubos.

6. Pode facer varios cortes gráficos en tubo cadrado, tubo oval, tubo en U e tubo rectangular, etc.

Standard Euipment

1. MESA DE CORTE

O sistema de mesa de corte dual está deseñado para aumentar o fluxo de traballo e reducir o tempo gastado na colocación e eliminación de materiais. A velocidade de intercambio da mesa de corte pode axustarse segundo o grosor dos materiais.

2. LIMPADOR DE BOQUILLAS

É importante manter a máquina cortando de forma rápida e limpa. O noso limpador de boquillas axuda a mellorar a vida das túas boquillas para que os teus cortes se manteñan máis.

ESPECIFICACIÓNS

| Modelo | KJG-1530 / IPG 1000w | |

| Capacidade máxima de corte | Aceiro leve | 10mm |

| Aceiro inoxidable | 4mm | |

| Aluminio | 3mm | |

| Cobre | 2mm | |

| Potencia láser | YLR-1000Watt | |

| Velocidade máxima de marcha | 40 / min | |

| Dimensións da peza de traballo | 1500 x 3000 mm | |

| Travesía rápida (eixo X e Y) | 105 m / min | |

| Aceleración | 1.2G (12m / s2) | |

| Precisión de posicionamento absoluta | ± 0,03 mm | |

| Máx. capacidade de carga | 1550 kg | |

| Extractor de fumes | 1000 m3 / hora | |

| Cabeza de corte con láser | RayTools BM110 de Suíza | |

| Taxa de alimentación | Programable ata 30 m / min. | |

| Materiais aplicados | Acero leve fino, aceiro inoxidable, aluminio, placa de cobre | |