Aplicación do produto

With the 1500mm x3000mm working area, the F3015 is the basic and the most economic model for ACCURL3015. Widely used in the processing of advertising board, metal plate structure, Hv/lv electrical ark production, textile machinery parts, kitchen utensils, car, machinery, elevator, electric parts, spring coil slice, subway line spare parts, etc..

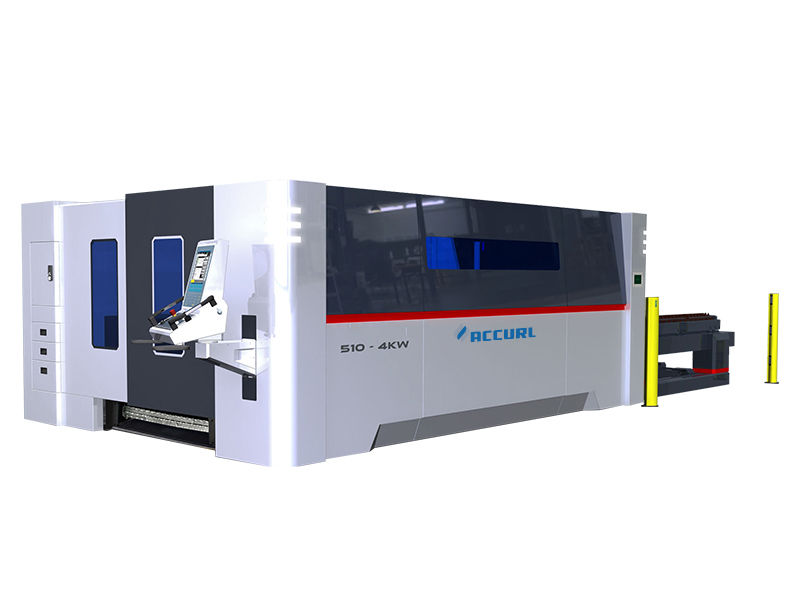

SPECIFICATION FOR ACCURL3015 FIBER LASER METAL CUTTING MACHINE | |||

Cabeza láser | BodorGenius Auto Focus Laser Head | ||

Fonte láser | IPG/Maxphotonics | ||

Área de traballo | 1500 * 3000mm | ||

Potencia láser | 500w/700w/800w/1000w/1500w/2000w/2500w/3000w/4000w | ||

Camiño de refrixeración | Refrixeración por auga | ||

Sistema de control | BodorPro | ||

Max Cutting Speeed | 35m / min | ||

Precisión | Position Accuracy:0.03mm. Reposition Accuracy:0.02mm | ||

Sistema de accionamento | Japan YASKAWA Servo Motor | ||

Transmisión | Taiwan silver HIWIN square rail, Taiwan YYC gear rack | ||

Bearing | Japan NSK Bearing | ||

Electric components | French Schneider electrical components | ||

Pneumatic components | Xapón compoñentes pneumáticos SMC | ||

Machine size+ weight | 4550*2300*2000mm , After package ,weight 3000kg | ||

Maximum acceleration | 1,5G | ||

Other parts | Auto lubrication system + pressure gage + laser protective goggles + WIFI Control+ control panel and etc. | ||

Principais características

1. Calidade de ruta excelente: menor punto láser e alta eficiencia no traballo, de alta calidade.

2. Alta velocidade de corte: a velocidade de corte é de 2-3 veces que a mesma máquina de corte con láser CO2.

3. Funcionamento estable: adopta láseres de fibra de importación superior mundial, rendemento estable, as pezas clave poden chegar ás 100.000 horas;

4. Alta eficiencia para a conversión fotoeléctrica: comparar coa máquina de corte con láser CO2, a máquina de corte con láser de fibra ten tres veces a eficiencia de conversión fotoeléctrica.

5. Baixo custo: aforrar enerxía e protexer o medio ambiente. A taxa de conversión fotoeléctrica ascende ata o 25-30%. De baixo consumo de enerxía eléctrica, é só aproximadamente un 20% -30% da máquina de corte láser tradicional CO2.

6. Mantemento baixo: a transmisión da liña de fibra non precisa lente reflectida, aforrar custos de mantemento;

7. Operacións sinxelas: transmisión de liña de fibra, sen axuste de ruta óptica.

Detalles rápidos

Estado: Novo

Tipo láser: láser de fibra

Material aplicable: metal

Espesor de corte: depende

Cutting Area: 1500x3000mm

Cutting Speed: 500mm/s

CNC ou Non: Si

Modo de refrixeración: Refrixeración por auga

Control Software: BodorPro

Graphic Format Supported: AI, BMP, DXF, PLT

Certification: CCC, CE, ISO, SGS, UL

Servizo posvenda: Enxeñeiros dispoñibles para maquinaria de servizo no exterior

Keyword: hot sale metal laser cutting machine

Cutting thickness: 0-30mm

Position accuracy: 0.02mm

Cutting speed: 0-10000mm/min

Cutting material: Metal stainless steel carbon steel aluminum

Application: Aluminum Sheets

Vise action Method: Semi Automatic Clamping Vise

Power: Mechanical

Brand: bodor

industriy: jewerlry metal products auto parts

Pezas da máquina

Name: BodorGenius Auto Focus Laser Head

1,Auto-Focus

Aplicable a varias distancias focais, controladas por sistema de control de máquinas-ferramenta. O punto focal axustarase automaticamente no proceso de corte para obter o mellor efecto de corte de chapas de diferentes grosores.

2,Free Your Hands

Focal length is controlled by operating system. We don't need to do manual regulation, which effectively avoids errors or faults caused by manual operation.

3,Fast

(1)Auto focus would automatically adjust the most appropriate focal points in the process of punching and cutting, which greatly improves cutting speed;

(2)When replacing different materials or different thicknesses sheet, manual focus laser head needs manual regulation, which is laborious and time-consuming; auto focus laser head is controlled by control system, it can read system storage parameters automatically, saving time and manpower;

(3)Collimating protective lens drawer can better protect collimating lens and improve replacing speed of protective lens.

4,Accuracy

Aumentar a lonxitude do foco de perforación, establecer por separado a distancia focal da perforación e cortar a distancia focal, mellorar a precisión do corte.

5,Durable

(1)Built-in double water-cooling structures can ensure the constant temperature of collimating and focusing components, avoiding overheating damage of lenses, cooling effect is better, no heating or fogging in long-term cutting, service life of lenses have lengthened.

(2)Increasing collimation protective lens and focus protective lens, carefully protect key components.

Name: Integrated Casting Machine Body

Using flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carbon content, high compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle.

Name: Control cabinet

Integrated the laser source and all the electronic machine parts, the cabinet can protect the precious electric parts and expensive laser source. The fan in the cabinet provide a better cooling system for the electrical parts

Name: Automatic lubrication system

Electrical lubrication is a kind of gear pump with rational construction, great performance and comprehensive functions.

By connection with program control system in the main machine, the lubrication system could oversee oil level within tank as well as oil transmission pressure and set lubrication periodicity, which will effectively prevent rust within lubrication system to ensure cutting accuracy.