Especificacións

stair metal used water cutter

1. 420MPA high pressure

2. USA imported intensifier

3. Do OEM

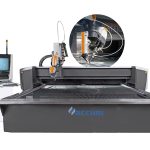

Components of High speed cutting machine type metal cutting waterjet

| Main technical parameter of waterjet cutting machine | |||

| Intensifier Pump

| Parámetro | ||

| Type of pressurization :hydraulic | |||

| Max oil discharge :106L/min | |||

| Max operating pressure :420Mpa | |||

| Continuous operating pressure :380Mpa | |||

| Maximum Diameter of orifice :0.35mm | |||

| Power requirme :37kw 380V/50HZ | |||

| Vantaxes | |||

| 1.Pumps are imported from American Accustream company with advanced & reasonable structure and high stability. | |||

| 2. Integrated heat exchanger, high heat exchange ratio and good effect, control the temperature of the hydraulicwithin the limit | |||

| 3. Two-stage water filter(5um,1um,0.45um)minimizes the damage of high pressure seals, nozzles and other parts. | |||

| 4.Two step-up water supply to make sure the pressure, automatic alarm and protection function when water is inadequate avoid the damage | |||

| 5.Multiple filter for outlet oil and return oil, pollution alarm, oil cooling and temperature alarming ensure the continuous operation | |||

| Cutting Table

| Parámetro | ||

| X axis characteristic :One-off extrusion forming aluminum alloy | |||

| Y axis characteristic :Cast iron used as foundation base | |||

| Z axis characteristic :double linear guide and four sliding block | |||

| Driving system :Z axis automatic controll,3axis association process | |||

| Driving wave :Servo drive system | |||

| Cutting head :Casting structure and concrete estrutura | |||

| Sealing way :Whole piece sealing | |||

| Vantaxes | |||

| 1. Separate body between cutting table and load-bearing platform prevents interfering cutting accuracy from long-term stress variation to load-bearing platform. | |||

| 2.X beam of cutting table applies the one-off extrusion forming aluminum alloy, light weight, strong steel, not deformed, is the most advanced technology in waterjet cutting machine. | |||

| 3. Cancelling dustproof cloth on X, Y, Z axis and hiding Y axis towline greatly improve the machine life and save the maintenance cost. | |||

| 4. Motor and ball screw are directly connected by flexible coupling. It can absorb vibration energy rever sible and with higher drive accuracy compared with other torsional rigid coupling. | |||

| CNC Controller

| Parámetro | ||

| Display Size :19inch LCD | |||

| Model of Cutting Text :DXF | |||

| Model of Computer :Industrial Control Computer | |||

| Operating System :Windows XP/ windows 7 | |||

| Cutting software advantage :Auto save and transfer common parameter | |||

| Vantaxes | |||

| 1. Industrial control computer: high reliability, convenient man-machine dialogue, real-time control of the cutting process | |||

| 2. CNC control, apply 19 inch LCD. facilitate operators to observe and reduce visual fatigue. | |||

| 3. Appropriate height of operating desk, reasonable display angle, and 180-degree horizontal rotation for easy operation and viewing | |||

| 4. Replace the relay with PLC, with a computer communications, flexible control | |||

| 5. Professional waterjet cutting software, easy to operate , easy to learn, and practical. | |||

| Automitic Abrasive Feeder

| Parámetro | ||

| Founction :Sand storage and sand delivery | |||

| Operating :No need electrocnic control, sample operation | |||

| Capacity :200 liters for 8 hours | |||

| Pressure :Less than 0.2Mpa compresses gas pressure | |||

| Level :Standard equipment of HEAD waterjet | |||

| Vantaxes | |||

| 1. Can supply the cutting sand quantity according to the adjustable sand level location tube | |||

| 2. No need electronic control, simple operation, reliable, maintenance-free | |||

| 3. 200liters capacity can provide enough sand for 8 hours continuous cutting | |||

| 4. Need less than 0.2Mpa compressed gas pressure, sand amount evenly, delivery smooth | |||

| 5. It is the standard components of HEAD water jet | |||

| Deionization System | Vantaxes | ||

| 1. Professional deionization system for water jet use | |||

| 2. Remove the calcium and magnesium ion, can improve the useful life of HP seals, orifice | |||

| 3. The outlet water amount can be 2ton/hour, can supply more than one machine | |||

4. Simple structure and reliable sealing, reasonable design of the flow passage | |||

| 5. Single tank control valve,no water pass the valve in washing | |||

| Wireless Handel | Vantaxes | ||

| 1. WHB06 the wireless remote control handle special design for HEAD waterjet control system | |||

| 2. It can realize wireless controlling water jet and long-distance materials processing | |||

| 3. With display function,real-time display X.Y.Z axis workpiece coordinate, mechanical coordinate ,speed,step value. | |||

| 4. Can set workpiece zero ,back to zero point, back to mechanical zero point,feed speed adjusting | |||

| 5. Adapt high performance wireless transmission technology,frequency hopping transmission. | |||

| 6. Special designed for HEAD water jet control system, it could realise wireless controling water jet and it can control long-distance material processing, improving work efficiency. | |||

| Auto abrasive removal system | Vantaxes | ||

| 1. Automatic desanding system is specifically designed for high-end customers. | |||

| 2. It can make maximize savings in manpower and extend the usage life for equipment | |||

| 3. Keeping the least content of sand in the water tank | |||

| 4. Maximum keeping the cutting environment clean. | |||

| Oil chiller | Vantaxes | ||

| 1. Professional oil chiller for water jet use | |||

| 2. Main motor adapts newest imported compressor, safe, high efficiency, lower noise | |||

| 3. Imported brand oil pump, higher pressure, higher stability, long term durability | |||

| 4. Imported digital controller,high accuracy, wide use range | |||

| 5. Can control the oil temperature in any range, can work well under 45 degree surroundings. | |||

| FAST CAM nesting software | Vantaxes | ||

| 1. Professional optimization nesting engine with a variety of ways and means of optimizing nesting | |||

| 2. Multiple formats for file of nesting, including , DWG, CAM and NC. | |||

| 3. Single or bulk reading or importing files for fast automatic nesting | |||

| 4. Setting parts line row, list row or matrix for automatic nesting. | |||

| 5. Editing the remaining plates, as well as nesting the remaining plates or irregular plates | |||