Descrición detallada do produto

| Número de modelo: | curl-1515L Máquina de corte de chorro de auga CNC | Área de corte eficaz (lonxitude): | 1500mm |

|---|---|---|---|

| Área de corte efectiva (ancho): | 1500mm | Ruidez superficial: | Ra≤25μm |

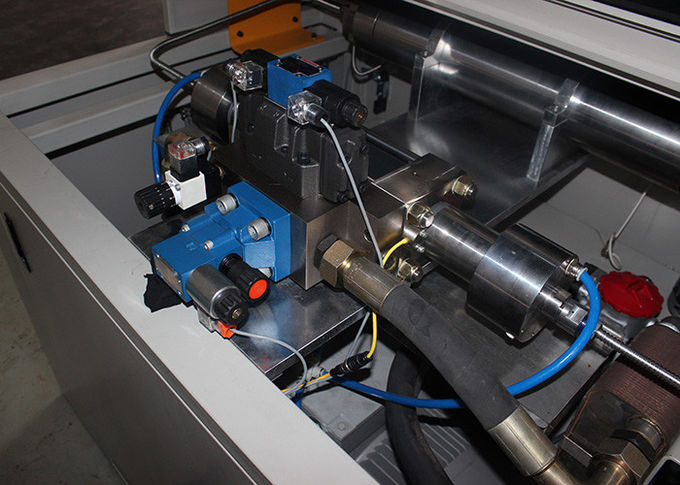

| Válvula: | Válvula de Alemaña Bosch-Rexroth | Palabras clave: | Cortador de chorro de auga para pedra |

Máquina de corte de mosaico de mármore China ACCURL cortadora de chorro de auga para pedra sintética turquesa

Descrición do produto

O ACCURL máquina de chorro de auga abrasivo é unha máquina de chorro de auga de alta presión que utiliza o corte de auga recta ou o corte por chorro de auga abrasivo para cortar varios tipos de materiais. O ACCURL Water-Jet é un sistema de parafuso de esferas rectificado de gran precisión para a máxima precisión e rixidez.

Corte de auga perfecto:

O mecanizado ACCURL® Waterjet conséguese forzar un gran volume de auga a alta presión a través dun pequeno orificio na boquilla de corte. O vapor acelerado de auga que sae da boquilla impacta no material e inicia o proceso de corte. O fluxo de auga acelerado é extremadamente estreito. Esta presión concéntrase entón nunha pequena área sobre o material que comeza a erosionar o material. Pódense cortar materiais máis suaves coa presión da auga. Os materiais máis duros requiren o uso dun sistema de alimentación abrasivo, como o corte de metais. O abrasivo introdúcese na corrente de auga a alta presión, que logo inicia a erosión dos materiais máis duros. Aínda que o mecanizado por chorro de auga é o proceso de corte máis lento, hai vantaxes certas que superan o seu ritmo:

1. Non hai zona afectada pola calor

2. Sen estres mecánicos

3. Kerf moi estreito

4. Non hai necesidade de Operacións Secundarias

5. Superficie lisa

6. Pode cortar varios materiais

Principais características

1. Pódese transferir o debuxo ao corte rapidamente

2. Posición rápida: algúns ou poucos equipos de fixación

3. Precisión de bisagra: reducir o recorte

4. Velocidade de corte máis rápida

5. Sen necesidade de fabricación das pezas de traballo

6. Máis seguro para o operador e circunstancias osteam, po, smog, etc

7. Corte frío: non se producirá calor

8. Procesamento claro, sen necesidade de limpar as pezas de traballo de novo

9. Bos acabados de corte-sen necesidade de triminar os acabados de corte de novo

10. Oco de corte estreito

11. Calibración rápida e forma de corte máis sinxela e versátil. Probouse que se pode usar na produción en masa no sistema ideal

12. Apto para software CAD/CAW

13. A máquina de corte por chorro de auga pode cortar case todos os materiais. Pode cortar a folla de 200 mm de espesor.

Sistema

Sistema HP: WJPOWER-420D (Sistema HP de intensificación dual)

Presión máxima: 420Mpa

Caudal máx.: 7,4 l/min

Potencia eléctrica: 75KW/100HP

Tensión: 220V ~ 480V / 50,60HZ.3PH

O conxunto do intensificador é totalmente importado de KMT (H20 USA)

característica

1. Característica funcional

1. O cabezal de corte inclinado nun ángulo en calquera dirección, eliminando o fenómeno f superficie de corte cóncava, convexa e irregular (para eliminar o fenómeno de superficie pequena e fondo grande). Para facer a unión frontal máis pequena, reducir o enlace de moenda, pode baldosa directamente. Reducindo moito o pulido e o custo de produción.

2. Fai que os gráficos complexos sexan máis delicados e fermosos.

3. Xira sen pausa, sen punto de xiro, fai que a velocidade de corte sexa máis rápida. A rugosidade da superficie de corte non afectará a colaxe.

2. Característica de procesamento

1. CNC formando patróns complexos.

2. Contaminación ambiental, sen gases tóxicos e po.

3. Pode procesar unha variedade de materiais de alta dureza, como: vidro, cerámica, aceiro inoxidable ou material relativamente brando, coiro, caucho, cueiros, etc.

4. Corte suave, sen escorias, non necesita procesamento secundario.

5. Aforra o custo.

As vantaxes de máquina de corte de chorro de auga

1. Pódese transferir os debuxos ao corte rapidamente

2. Posición rápida: algúns ou poucos equipamentos de fixación

3. Alta precisión: reduce o recorte

4. Velocidade de corte máis rápida

5. Sen necesidade de fabricación das pezas de traballo

6. Máis seguro para o operador e circunstancia: sen vapor, po, smog, etc

7. Corte frío: non se producirá calor

8. Procesamento claro: sen necesidade de limpar as pezas de traballo de novo

9. Bos acabados de corte: sen necesidade de reelaborar os acabados de corte de novo.

10. Oco de corte estreito

11. Calibración rápida e forma de corte máis sinxela e versátil. Probouse que se pode usar na produción en masa no sistema ideal

12. Apto para software CAD/CAM

13. A máquina de corte por chorro de auga pode cortar case todos os materiais

Especificación

| Modelo | curl-4020L | ||

| mesa de traballo | mm | 3000 x 1500 | |

| Eixe X | ictus | 2000 | 3000 |

| Velocidade | 0~15 | 0~15 | |

| Eixe Y | ictus | 1000 | 1500 |

| Velocidade | 0~15 | 0~15 | |

| Eixe Z | ictus | 150-180 | 150-180 |

| Velocidade | 0~12 | 0~12 | |

| Precisión do control | mm | ± 0,01 | |

| Precisión de posicionamento | mm | ± 0,02 | |

| Sistema de Alta Presión | Presión máxima | 380 | 380 |

| Potencia | 37 (50 CV) | 37 (50 CV) | |

| Potencia eléctrica total | KW | 38 | |

| Carga máxima da mesa de traballo | Kgs | 1000 | |

| Formato soportado | AI, PLT, DXF, etc. | ||

| Peso da máquina | Kgs | 5650 | |

| Dimensión exterior | mm | 4050x2250x1850 | |

| Nome do produto | Cortador de chorro de auga para pedra | ||